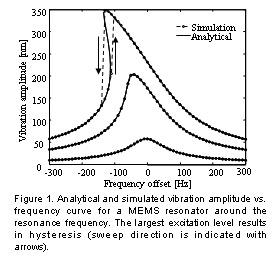

Micromechanical resonators or microresonators have a limit to the

maximum usable vibration amplitude. This limit may be set by material

strength, or as is often case for a MEMS resonator, by unwanted

nonlinear effects. Figure 1 shows how the microresonator resonance

response is changed in the presence of nonlinear restoring forces

(=nonlinear springs). As the vibration amplitude increases, the

resonance peak frequency shifts from the linear resonance

frequency. This is often referred to as the Duffing effect. At

sufficiently large amplitudes, the amplitude-frequency curve shows

hysteresis; the vibration amplitude depends on the direction of

frequency sweep (up/down).

Although there has been some ideas of

taking advantage of nonlinear effects (e.g parametric excitation),

usually the devices need to be operated below the hysteresis point in

order to obtain predictable performance. Translated to electrical

engineering terms, the drive level (or power handling capacity) of

MEMS devices is limited by the nonlinear effects. As the signals

levels from microresonators are small in general, it is of fundamental

interest to know the maximum achievable drive level for micro-sized

devices. This determines, for example, whether one can make a MEMS

oscillator with small enough phase noise for reference

applications.

Micromechanical resonators or microresonators have a limit to the

maximum usable vibration amplitude. This limit may be set by material

strength, or as is often case for a MEMS resonator, by unwanted

nonlinear effects. Figure 1 shows how the microresonator resonance

response is changed in the presence of nonlinear restoring forces

(=nonlinear springs). As the vibration amplitude increases, the

resonance peak frequency shifts from the linear resonance

frequency. This is often referred to as the Duffing effect. At

sufficiently large amplitudes, the amplitude-frequency curve shows

hysteresis; the vibration amplitude depends on the direction of

frequency sweep (up/down).

Although there has been some ideas of

taking advantage of nonlinear effects (e.g parametric excitation),

usually the devices need to be operated below the hysteresis point in

order to obtain predictable performance. Translated to electrical

engineering terms, the drive level (or power handling capacity) of

MEMS devices is limited by the nonlinear effects. As the signals

levels from microresonators are small in general, it is of fundamental

interest to know the maximum achievable drive level for micro-sized

devices. This determines, for example, whether one can make a MEMS

oscillator with small enough phase noise for reference

applications.

The nonlinearities can be of either

mechanical or electrical origin. Most fundamentally, the MEMS

materials are nonlinear due nonlinearities in atomic

interactions. Luckily, silicon is quite linear material and other

nonlinear effects typically dominate. For further information on

nonlinear vibrations and nonlinear effects in MEMS resonators in

particular, please refer to the publications.